- Contact-us

- info@wagendass.com

- 8h-12h & 14h-17h30 Monday to Friday

Air Conditioning 854 Products

The air conditioning system cools the air in the passenger compartment.

This technology in the automotive industry date all the way back to 1933 in New York, USA

The entire system includes an air conditioning compressor, condenser, evaporator, evaporator, filter drier. A fluid runs in a closed loop in the system.

It is important when replacing these components to drain the circuit and comply with the manufacturer's instructions.

Air conditioning compressors for cars, air conditioning compressors for tractors, air conditioning compressors for agricultural machines are available in the various categories of the site.

Subcategories

A/C Compressor for...

A/C Compressor for...

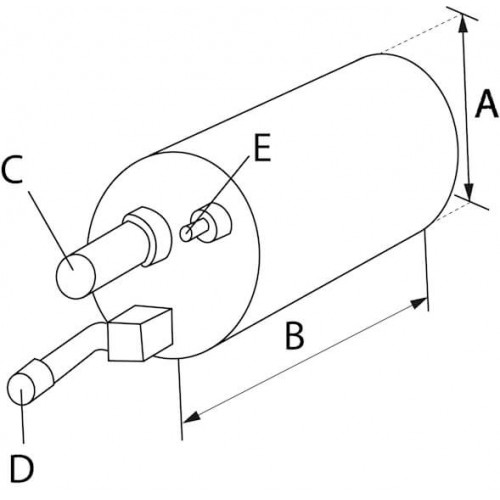

An air conditioning compressor is an essential component of a car air conditioning system. Its role is to compress the refrigerant, which circulates in the system, into a high pressure, high temperature gas. This gas is then cooled and condensed in the system's condenser, where it releases the absorbed heat into the car's interior.

The air conditioning compressor is usually driven by a belt connected to the car's engine. It is located near the engine and can be identified as a metal housing with refrigerant lines coming out of it.

If the air conditioning compressor is not working properly, it can lead to a loss of air conditioning efficiency or even a complete system failure. Signs of a malfunctioning compressor may include unusual noises, coolant leaks or an air conditioner that does not produce enough cool air.Dryers

AC compressor replacing DAC8629713 / 6925721 / 5447150031 AC compressor replacing DAC8629713 /...

Replacing 100662 Delphi 2483000040 Denso 2483000400 Denso 4371006770 Denso 4371006930 Denso 4471500394 Denso 4471601620 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING...

279,90 €AC compressor replacing PXE16-1603P / PXE16-1603F / 6854109 AC compressor replacing PXE16-1603P /...

Replacing 13232305 Opel 13262836 Opel 6854109 Opel PXE16-1603F Sanden PXE16-1603P SandenNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

259,90 €AC compressor replacing PXE14-1738 / PXE14-1723 / 6R0820803F AC compressor replacing PXE14-1738 /...

Replacing 6R0820803D Volkswagen 6R0820803F Volkswagen PXE14-1723 Sanden PXE14-1738 SandenNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €AC compressor replacing SD7H15-8215 / 85000723 / 5010628046 AC compressor replacing SD7H15-8215 /...

Replacing 20593523 Volvo 5010628046 Renault 85000723 Volvo SD7H15-8215 SandenNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing 97701-1R100 / 1M292-0456 AC compressor replacing 97701-1R100 /...

Replacing 1M292-0456 Doowan compressor 97701-1R100 KiaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing 1618493 / 1618426/ 1618400 AC compressor replacing 1618493 / 1618426/...

Replacing 13346492 Chevrolet 13396664 Opel 13414017 OpelNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €AC compressor replacing 5511683AE / 55116835AD / 4472205605 AC compressor replacing 5511683AE /...

Replacing 2473003350 Denso 2473003352 Denso 4471806890 Denso 4472205600 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing 4G0260805D / 447260-3890 / 447150-3702 AC compressor replacing 4G0260805D /...

Replacing 447150-2350 Denso 447150-2360 Denso 447150-2367 Denso 447150-3700 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing 5Q0820803Q / 5Q0820803F / 01141482 AC compressor replacing 5Q0820803Q /...

Replacing 01141482 Delphi 447150-4200 Denso 447150-6030 Denso 5Q0820803 VolkswagenNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

249,90 €AC compressor replacing SD5H14-4536 / SD5H14-6630 AC compressor replacing SD5H14-4536 /...

Replacing SD5H14-4536 Sanden SD5H14-6630 SandenNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

189,90 €AC compressor replacing Z0002259D / 36002425 / 36000456 AC compressor replacing Z0002259D /...

Replacing 30780443 Volvo 31250519 Volvo 31291135 Volvo 31305833 VolvoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing 97701-A5501 / 97701-A6500 AC compressor replacing 97701-A5501 /...

Replacing 97701-A5501 Kia 97701-A6500 KiaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

299,90 €AC compressor replacing 8200628441 / 8200201422 / 7421049380 AC compressor replacing 8200628441 /...

Replacing 7421049380 Renault 8200201422 Renault 8200628441 RenaultNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

249,90 €AC compressor replacing AV1119D629BC / 2025775 / 1855762 AC compressor replacing AV1119D629BC /...

Replacing 1774907 Ford 1855762 Ford 2025775 Ford AV1119D629BA Ford AV1119D629BC FordNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing SD7H15-8243 / SD7H15-6035 / 11412632 AC compressor replacing SD7H15-8243 /...

Replacing 11412632 Volvo SD7H15-6035 Sanden SD7H15-8243 SandenRemark : NB! 2 pin connector. NO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing 51883101 / 52003007 AC compressor replacing 51883101 / 52003007

Replacing 51883101 Fiat 52003007 FiatNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

259,90 €AC compressor replacing 977012E551 / 977012E550 / 97701-2E300 AC compressor replacing 977012E551 /...

Replacing 97701-2E300 Kia 977012E550 Kia 977012E551 KiaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

369,90 €AC compressor replacing 8K0260805P / 8K0260805F / 4472602790 AC compressor replacing 8K0260805P /...

Replacing 2483002400 Denso 4371005660 Denso 4471500660 Denso 4472602790 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

249,90 €AC compressor replacing 8603968 / 36002423 / 36000454 AC compressor replacing 8603968 / 36002423...

Replacing 30645289 Volvo 30742208 Volvo 30742236 Volvo 30780442 Volvo 31250521 VolvoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

269,90 €AC compressor replacing SD7V16-1243 / DAC8600065 / 9642800780 AC compressor replacing SD7V16-1243 /...

Replacing 6453NH Peugeot 6453NJ Peugeot 699094 Valeo 7701499820 Fiat 9642800780 FiatNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

239,90 €AC compressor replacing AV6119D629HB / AV6119D629HA / 447280-7070 AC compressor replacing AV6119D629HB /...

Replacing 1786888 Ford 1928558 Ford 2069520 FordNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

369,90 €AC compressor replacing 5801362246 AC compressor replacing 5801362246

Replacing 5801362246 IvecoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing 97701-4P002 / 97701-4P001 / 97701-4P000 AC compressor replacing 97701-4P002 /...

Replacing 97701-4P000 Kia 97701-4P001 Kia 97701-4P002 KiaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

399,90 €AC compressor replacing TRSE094991 / TRSE093786 / TRSE093764 AC compressor replacing TRSE094991 /...

Replacing 38800RZB510M2 Honda 38800RZYA01 Honda 38800RZYA010M2 Honda 38800RZYA011M202 HondaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

239,90 €AC compressor replacing A4572300111 / 4572300111 / 447170-9142 AC compressor replacing A4572300111 /...

Replacing 0002343711 Mercedes Benz 447170-9142 Denso 4572300111 Mercedes Benz A4572300111 Mercedes BenzNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing 1618495 / 13414018 / 13412251 AC compressor replacing 1618495 / 13414018...

Replacing 13346491 Opel 13346493 General motor 13346493 Vauxhall se Opel 13412249 OpelNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €Dryer replacing 1C0820191 / 1K0298403 / 1015001035 Dryer replacing 1C0820191 / 1K0298403 /...

brand cargo BoschReplacing 1015001035 Visteon1C0820191 Volkswagen1K0298403 Volkswagen1K0298403A Volkswagen3C0898191B Volkswagen3C0898191C Audi see VW5C0298403 Audi see VW

28,90 €AC compressor replacing 50547718 / 50533539 / 50509535 AC compressor replacing 50547718 /...

Replacing 50509535 Alfa Romeo 50509535 Fiat 50533539 Fiat 50547718 FiatNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

239,90 €AC compressor replacing 9122618 / 6932176 / 64529122618 AC compressor replacing 9122618 / 6932176...

Replacing 2483001230 Denso 4371006660 Denso 4471500160 Denso 4471506100 Denso 4471908540 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

289,90 €AC compressor replacing 1618494 / 13414019 / 13346494122618 AC compressor replacing 1618494 / 13414019...

Replacing 13335253 Opel 13346494 Opel 13414019 Opel 1618494 OpelNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

269,90 €AC compressor replacing 64529222308 AC compressor replacing 64529222308

Replacing 64529222308 BMWNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €AC compressor replacing CV6119D629EA / 1747949 AC compressor replacing CV6119D629EA /...

Replacing 1747949 Ford CV6119D629EA FordNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing SD7C161322 / SD6C121366 / 9684139980 AC compressor replacing SD7C161322 /...

Replacing 6453ZE Peugeot 648754 Peugeot 648755 Peugeot 648757 PeugeotNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €AC compressor replacing A0032308711 / 32308711 / 0032308711 AC compressor replacing A0032308711 /...

Replacing 0032308711 Mercedes Benz 32308711 Mercedes Benz A0032308711 Mercedes BenzNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

249,90 €AC compressor replacing A0008302700 / 0008302700 AC compressor replacing A0008302700 /...

Replacing 0008302700 Mercedes Benz A0008302700 Mercedes BenzNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

339,90 €AC compressor replacing ACP875 / 918279403 / 9182794 AC compressor replacing ACP875 / 918279403...

Replacing 64509156820 BMW 64526961619 BMW 64529182794 BMWNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

249,90 €AC compressor replacing 92600-JD75A / 92600-JD74A / 92600-JD73A AC compressor replacing 92600-JD75A /...

Replacing 92600-BB60A Nissan 92600-JD700 Nissan 92600-JD70B Nissan 92600-JD71A NissanNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

229,90 €AC compressor replacing 38810-RB0-E02 AC compressor replacing 38810-RB0-E02

Replacing 38810-RB0-E02 HondaNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

219,90 €AC compressor replacing A5412301111 / A0002340811 / 4471905510 AC compressor replacing A5412301111 /...

Replacing 0002301511 Mercedes Benz 0002304211 Mercedes Benz 2473002370 Denso 2473004670 DensoNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

199,90 €AC compressor replacing 95200-M68KC0 / 447280-0490 / 27630-4A00G AC compressor replacing 95200-M68KC0 /...

Replacing 276304A00G Nissan 4472800490 Denso 95200-M68KA1 SuzukiNO WARRANTY CAN BE CLAIMED IF THE FILTER/DRYER IS NOT CHANGED WHEN INSTALLING THE NEW COMPRESSOR

159,90 €

We've received a number of technical inquiries about the oil used in our air-conditioning compressor replacements, particularly for belt-driven compressors. Please note that all +Line compressors are pre-filled with the appropriate oil. However, the total quantity of oil required may vary according to the specific application.

To ensure you use the right type and quantity of oil, we recommend you follow the procedure below:

1. Drain the oil: Carefully drain the oil from the compressor. This step is important to ensure that any residual oil from the production process is removed.

2. Filling the system: Use an air-conditioning maintenance machine to fill the system with the right type and quantity of oil. This ensures that the oil is distributed evenly throughout the system.

Other technical considerations:

- Oil compatibility: Make sure the oil you use is compatible with your system's refrigerant (e.g. PAG oil for R134a systems). Using the wrong oil can lead to poor lubrication, increased wear and, eventually, compressor failure.

- System flush: if the system has been exposed to contaminants, or if a compressor has failed, it is essential to flush the system thoroughly before adding new oil and refrigerant.

- Oil viscosity: Check that oil viscosity is within compressor specifications. Correct viscosity is essential to maintain efficient lubrication and avoid damage to the compressor.

This procedure applies specifically to belt-driven compressors. By following these steps, you can ensure optimum performance and extend the life of your air conditioning system.

If you have any further questions, please do not hesitate to contact us.